Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2025-12-24 11:48:05

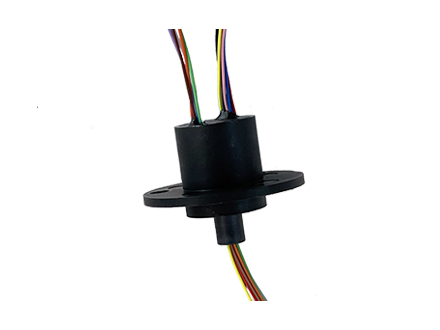

In the realm of electrical engineering, AC generators play a pivotal role in converting mechanical energy into electrical energy. Central to the efficient operation of these generators is a critical component known as the slip ring. Slip rings enable the transfer of power and signals between a stationary and a rotating structure, ensuring smooth and continuous electrical connectivity. This article delves into the purpose of slip rings in AC generators, their types, applications, and the advantages of various specialized designs including electrical slip rings, Through Bore Slip Rings, pneumatic slip rings, and brushless slip rings.

AC generators, also known as alternators, operate on the principle of electromagnetic induction, where a conductor rotates within a magnetic field to generate alternating current (AC). To maintain this rotation, mechanical energy—typically from a turbine or engine—is supplied to the rotor. However, for the generator to deliver electricity to an external circuit while the rotor spins, a continuous electrical connection must be maintained. This is where slip rings come into play.

A slip ring is essentially a rotary electrical connector that allows current to flow between stationary wires and the rotating rotor. Without slip rings, transferring electrical power from a rotating component to a stationary load would require cumbersome and unreliable methods, such as coiled wires prone to tangling or breakage.

Maintaining Continuous Electrical Contact

The primary purpose of slip rings in AC generators is to maintain continuous electrical contact with the rotor windings. As the rotor spins, slip rings provide a smooth interface between the rotating rotor and stationary brushes, allowing the AC current generated to be transmitted efficiently to the external load.

Enabling Rotor Excitation

In many AC generators, especially synchronous generators, the rotor requires a DC excitation current to generate a magnetic field. Slip rings facilitate this by allowing the DC current to be fed into the rotor windings while the rotor is rotating. This ensures that the magnetic field is stable, which is critical for generating a consistent AC output.

Minimizing Wear and Tear

Traditional connections without slip rings would create mechanical stress and wear on wires due to constant rotation. Slip rings reduce friction and wear, providing a reliable and long-lasting solution for electrical connectivity in high-speed rotating machinery.

Several types of slip rings are used depending on the generator’s design, size, and application:

Electrical slip rings are the most common type, designed specifically for transferring electrical power. They are often used in small to medium-sized AC generators where maintaining consistent electrical contact is crucial. These slip rings are highly reliable and can operate under different voltage and current ratings.

For applications where the rotor or shaft must be hollow to accommodate cables or other components, Through Bore Slip Rings (also known as Through Hole Slip Rings) are ideal. These slip rings allow the generator’s rotor shaft to pass through the center, providing electrical connectivity without obstructing the shaft. They are commonly used in wind turbines and large industrial generators where space optimization is essential.

Some advanced generators require the transfer of both electrical signals and compressed air for cooling or control systems. Pneumatic slip rings combine electrical slip ring functionality with air channels, enabling the simultaneous transfer of electricity and pneumatic power. These are particularly useful in large-scale industrial AC generators and turbine systems.

Brushless slip rings are an innovative solution that eliminates the traditional carbon brushes, reducing maintenance and friction. In generators with a slip ring motor, brushless designs increase efficiency, reliability, and longevity. They are suitable for high-speed generators and applications where minimizing wear is critical.

Every generator has unique requirements, and in some cases, custom slip rings are necessary. These slip rings can be designed for specific voltage, current, environmental conditions, or mechanical configurations. Companies like Senring slip ring specialize in custom solutions, providing slip rings that meet precise technical and operational needs.

Slip rings are not only essential in conventional AC generators but also play a significant role in a variety of specialized applications:

Wind Turbines: The rotating nacelle requires continuous electrical transfer, which is made possible through through bore or brushless slip rings.

Hydroelectric Generators: High-voltage generators use electrical slip rings to ensure efficient and stable power transfer.

Marine Generators: Pneumatic and electrical slip rings are used in generators on ships, allowing compact design and efficient operation.

Industrial Equipment: Custom slip rings are integrated into machinery requiring AC generators for operation in harsh environments.

Reliability: Slip rings provide a dependable electrical connection, crucial for continuous AC power generation.

Efficiency: Reduced friction and wear mean lower maintenance costs and higher generator uptime.

Versatility: The availability of electrical, pneumatic, through bore, and brushless slip rings allows application across diverse generator designs.

Customizable Solutions: With custom slip rings, generators can meet specific operational demands, enhancing performance and longevity.

Selecting the right slip ring depends on several factors:

Electrical requirements: Voltage, current, and signal type.

Mechanical constraints: Shaft size, rotation speed, and environmental conditions.

Maintenance needs: Brushless slip rings reduce maintenance compared to traditional designs.

Special functionality: If pneumatic channels or other custom features are needed, specialized slip rings are preferred.

Reputable manufacturers like Senring slip ring provide a wide range of solutions, from standard electrical slip rings to complex custom slip rings, ensuring compatibility with all AC generator types.

In conclusion, slip rings are indispensable components in AC generators, enabling the seamless transfer of electricity between stationary and rotating parts. From maintaining continuous electrical contact to enabling rotor excitation, slip rings ensure efficient and reliable operation of AC generators across various industries. Whether using through bore slip rings, pneumatic slip rings, brushless slip rings, or custom slip rings, the right selection improves performance, reduces maintenance, and supports long-term generator functionality. As generator technology advances, innovations in slip ring design continue to enhance efficiency, reliability, and versatility, cementing their role as a cornerstone of modern AC power generation.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions