Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2025-12-17 15:25:26

In many modern machines, rotation and electrical transmission must happen at the same time. From wind turbines and robotics to medical scanners and industrial automation, this challenge is solved by a component known as a slipring. But what is a slipring, how does it work, and why is it so important?

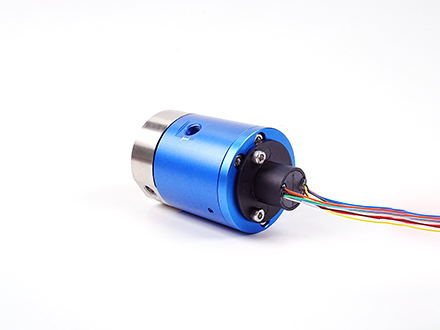

A slipring (also written as Slip Ring or sliprings) is an electromechanical device that allows the transmission of electrical power, signals, or data between stationary and rotating parts of a system. It enables continuous rotation without twisting or damaging wires.

In simple terms, a slipring acts as a rotating electrical connector, maintaining a stable electrical connection while mechanical rotation occurs.

To understand what is a slipring, it helps to look at how it works.

A typical electrical slip ring consists of:

A rotating conductive ring (rotor)

A stationary contact (brush or wire)

A housing to protect internal components

As the rotor turns, the stationary brush maintains contact with the conductive ring. This continuous contact allows electricity or signals to pass through without interruption, even during unlimited rotation.

This simple yet effective design is the foundation of all Rotary Slip Ring and slip ring rotating connector systems.

An electrical slip ring is specifically designed to transmit electrical power and signals. It can handle:

Low or high current

AC or DC power

Analog or digital signals

Advanced electrical slip rings use precious metal contacts, gold-to-gold interfaces, or fiber-optic technology to reduce electrical noise and wear, ensuring reliable performance in sensitive applications.

Traditional wiring cannot support continuous rotation without twisting, bending, or breaking. A slip ring electrical connector solves this problem by separating electrical continuity from mechanical motion.

Key advantages over traditional wiring:

Unlimited rotational movement

Reduced mechanical stress

Longer service life

Cleaner and more compact system design

This is why sliprings are widely used instead of cable loops or flexible wires.

There are many types of sliprings, each designed for specific applications.

A rotary slip ring is the most common type. It allows 360-degree or continuous rotation while transmitting electrical power and signals.

Applications include:

Industrial machinery

Packaging equipment

Turntables

Surveillance systems

A through-hole design features a hollow center, allowing shafts or pipes to pass through the slipring. This type is often used in wind turbines, robotic arms, and automation systems.

Compact and lightweight, capsule sliprings are ideal for space-limited applications such as cameras and medical devices.

An electrical rotary union is often used interchangeably with sliprings, especially when electrical transmission is combined with fluids or gases. These hybrid designs are common in automated production lines and medical equipment.

A slip ring rotating connector plays a vital role in systems that require both motion and power or signal transmission.

Common uses include:

Wind power generators

Radar and antenna systems

Robotics and automation

Medical imaging equipment

Aerospace and defense applications

In each case, the slipring ensures uninterrupted operation while components rotate freely.

The performance and lifespan of sliprings depend heavily on material selection.

Common materials include:

Copper or copper alloys for conductive rings

Gold or silver plating for low resistance

Graphite or precious metal brushes

Aluminum or engineering plastic housings

High-quality materials improve conductivity, reduce wear, and extend service life.

Understanding what is a slipring also means understanding its benefits.

Key advantages include:

Continuous electrical connection during rotation

Reduced cable wear and maintenance

Support for multiple circuits

Improved system reliability

Flexible and modular design options

These benefits make sliprings essential components in modern electromechanical systems.

In industrial environments, sliprings support:

Robotic arms

Rotary tables

Automated assembly lines

Packaging and labeling machines

By acting as a rotating electrical connector, sliprings enable precise control and consistent performance.

Wind turbines rely heavily on electrical slip rings to transmit power and control signals from rotating blades to stationary systems. Without sliprings, modern wind energy systems would not be possible.

Although sliprings are designed for durability, proper maintenance can significantly extend their lifespan.

Maintenance tips:

Keep operating environments clean and dry

Monitor contact wear

Avoid overload conditions

Follow manufacturer service recommendations

High-quality rotary slip rings can operate for millions of rotations with minimal maintenance.

Myth 1: Sliprings wear out quickly

Modern materials and designs have greatly extended slipring lifespans.

Myth 2: Sliprings cause signal noise

High-quality electrical slip rings are designed for low noise and high signal integrity.

When selecting a slipring, consider:

Number of circuits

Voltage and current requirements

Signal type

Rotational speed

Environmental conditions

Custom Slip Ring electrical connectors are often available for specialized needs.

As technology advances, sliprings are becoming:

Smaller and more compact

More durable and maintenance-free

Capable of handling high-speed data

Integrated with fiber-optic and hybrid systems

These innovations ensure sliprings remain relevant in next-generation machinery.

So, what is a slipring? It is a critical electromechanical component that allows power and signals to pass between stationary and rotating parts without interruption. From a simple electrical slip ring to advanced electrical rotary union systems, sliprings are essential to modern engineering.

Whether used as a rotary slip ring, slip ring rotating connector, or integrated into complex machinery, sliprings quietly enable the motion and connectivity that power today’s world.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions