Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2025-12-04 10:39:25

In modern automation and electromechanical engineering, maintaining continuous connectivity between rotating and stationary components is essential. This is where slip rings come into play. But what do slip rings do, and why are they so widely used in industrial systems, robotics, wind turbines, and automation equipment?

As a professional supplier of Rotary Slip Ring solutions, including high-performance RQ Series Rotary Joints, electrical slip rings, electrical Rotary Unions, brushless slip rings, and Through Bore Rotary Unions, we provide engineers and OEMs with reliable solutions for uninterrupted power and signal transmission in rotating structures.

A slip ring is an electromechanical device that enables the transmission of electrical power, signals, or data between a stationary part and a rotating part. Without a slip ring, cables would twist endlessly as the device rotates, leading to cable failure, downtime, and system malfunction.

This makes them essential in any equipment where rotating components need electrical connection.

Slip rings solve several engineering challenges:

Allows unlimited 360° movement of rotating components.

Ensures uninterrupted power or signal flow between stationary and rotating units.

Avoids wear, breakage, and frequent maintenance.

Including power, Ethernet, USB, Profibus, RS485, CAN bus, high-frequency signals, and more.

Allows engineers to design smaller, more efficient rotating machinery.

Slip rings consist of rotating rings and stationary brushes.

As the equipment rotates, brushes maintain electrical contact with the rings, allowing current and signals to pass through.

Basic working mechanism:

Stationary brushes carry current from the fixed wiring.

Rotating rings are mounted on the rotating shaft.

Brushes slide on the rings, maintaining continuous contact.

Power or data passes through brushes → rings → rotating component.

This simple yet powerful mechanism is the foundation of all rotary electrical connections.

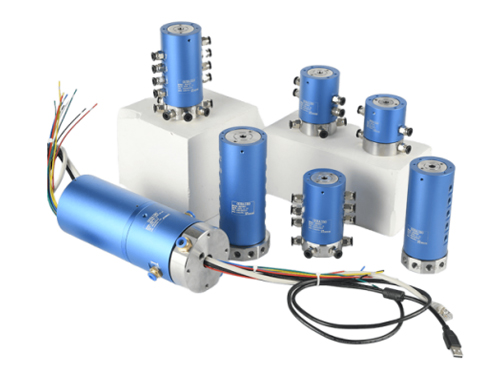

Different applications require different slip ring technologies. Below are the main types we supply.

An electrical slip ring is the most common type, used for power and low-frequency signal transmission.

It is widely used in:

Packaging machines

CCTV PTZ cameras

Turntables

Robots

Automation equipment

We provide various standard and custom electrical slip ring models to meet voltage, current, and circuit requirements.

A rotary slip ring supports continuous rotation while transmitting electrical signals.

It is ideal for:

Industrial machinery

Radar systems

Measuring instruments

Manufacturing equipment

Rotary slip rings are known for their durability, compact design, and stable performance even in harsh environments.

An electrical rotary union combines electrical slip rings with fluid or air channels.

They support:

Power + signals

Hydraulic fluid transfer

Pneumatic air transfer

Cooling liquids

This hybrid structure is essential for automated manufacturing, robotic arms, injection molding machinery, and heavy industrial systems.

Our RQ Series Rotary Joints are advanced multi-channel rotary unions designed for:

Air

Vacuum

Water

Steam

Coolants

Combined with electrical circuits, they form a complete electro-fluid rotary transfer solution.

They are widely used in:

Packaging & filling machines

High-speed rotary tables

Semiconductor equipment

Automation lines

RQ Series Rotary Joints offer:

High pressure resistance

High-speed rotation

Low torque

Outstanding sealing performance

A brushless slip ring replaces traditional carbon brushes with non-contact transmission technology.

Advantages include:

No friction

Longer lifespan

Zero dust generation

Maintenance-free operation

Ultra-low electrical noise

This makes brushless slip rings ideal for:

Medical imaging machines (CT, MRI)

High-speed robotics

Defense and aerospace equipment

Precision measuring devices

A through bore rotary union features a hollow center, allowing:

Shafts, pipes, or cables to pass through

Clamping and rotating of mechanical structures

Common applications:

Robotics

Wind turbines

Machine tool spindles

Automation turntables

This design increases integration flexibility and mechanical strength in complex rotating systems.

Slip rings are used across hundreds of industries. Below are the most common application fields.

Robotics, assembly systems, rotary indexing tables.

Transmit power and control signals to blade pitch systems.

CT scanners require high-speed 360° rotation with stable data transmission.

Enable endless rotation without cable tangling.

Used in high-speed rotary filling and sealing equipment.

Missile systems, radar antennas, UAV gimbals.

Winches, cable reels, and sonar devices.

Rotating stages, amusement rides, large displays.

Slip rings are indispensable wherever rotation and electrical connection coexist.

As a leading manufacturer and supplier of rotary transmission systems, we provide solutions engineered for industrial reliability and long service life.

Power + signal integrated solutions.

Low electrical noise and ultra-smooth transmission.

Electrical slip rings

Rotary slip rings

Electrical rotary unions

Brushless slip rings

Through bore rotary unions

RQ Series Rotary Joints

Long life cycles, low wear, high stability.

We design and produce slip rings tailored to your equipment requirements.

When selecting a slip ring, consider:

Number of circuits

Voltage and current rating

Rotation speed

Installation space

Environmental conditions (humidity, vibration, temperature)

Signal type (Ethernet, servo motor feedback, power, USB, etc.)

Need for fluid or pneumatic channels

Our engineering team provides expert consultation to ensure the perfect solution for your application.

What do slip rings do?

They provide continuous electrical and signal transmission between stationary and rotating parts, enabling 360° unlimited rotation without cable twisting or interruption.

Whether you need a high-speed brushless slip ring, a durable rotary slip ring, a multi-channel electrical rotary union, or an advanced RQ Series Rotary Joint with fluid transfer capabilities, our factory delivers reliable, long-lasting solutions designed for industrial excellence.

Slip rings remain a central component in automation, robotics, renewable energy, medical devices, heavy equipment, and advanced industrial machinery—keeping the world’s rotating systems running smoothly and efficiently.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions