Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2025-10-28 14:29:00

In today’s age of intelligent manufacturing and high-speed automation, efficient power and signal transmission are critical. One of the key technologies that enable continuous rotation while maintaining uninterrupted electrical connectivity is the Rotating Electrical Connection. Also known as a rotating connector electrical or spinning electrical connection, this device allows the transmission of current, data, and signals between stationary and rotating components in various types of machinery. From robotics and wind turbines to radar systems and medical equipment, the Rotating Electrical Connection plays a vital role in ensuring stability, precision, and efficiency.

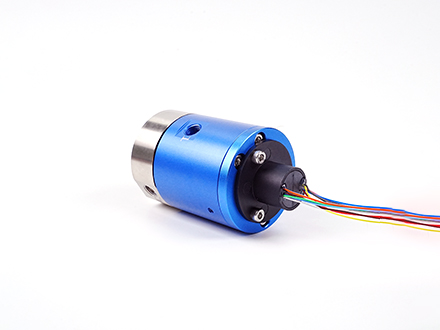

A rotating electrical connection is an electromechanical device that allows the transmission of electrical power or signals across a rotating interface. Essentially, it bridges stationary and rotating parts of a system without the need for tangled wires or complex cable management.

These components are commonly referred to as rotary joints, electrical swivels, or Slip Rings. The primary function is to maintain a consistent flow of current or data even when one side of the equipment rotates 360° or continuously spins during operation.

Modern rotating connectors use precision-engineered contact materials such as gold-to-gold or silver-graphite interfaces, ensuring long service life, low electrical noise, and high transmission reliability. Depending on the application, designs can include capsule, through-bore, pancake, or fiber-optic rotating assemblies.

One of the most common applications of rotating connector electrical systems is in industrial robots and automation machinery. Robots often require continuous or repetitive rotation in joints or bases while maintaining power and signal transmission to sensors, servomotors, and control systems.

The spinning electrical connection allows robotic arms to move freely without twisting cables, which would otherwise lead to mechanical stress, signal interference, and maintenance issues. These components enable seamless motion control and real-time communication for complex multi-axis systems.

Key advantages:

Continuous 360° rotation without wire entanglement

High-speed signal transmission for encoders and sensors

Compact design suitable for robotic joints

Improved system lifespan and reduced downtime

In wind power generation, the nacelle at the top of the tower rotates to align the blades with wind direction, while the electrical generator remains connected to stationary systems. Here, the rotating electrical connection plays a crucial role in transferring generated power and control signals between the rotating blades and fixed tower structure.

High-current slip ring assemblies are designed to handle large power outputs while withstanding extreme environmental conditions such as humidity, dust, and vibration.

Application benefits:

Reliable transmission of high-voltage and control signals

Enhanced corrosion resistance and long maintenance intervals

Improved energy efficiency through stable electrical contact

Compatibility with monitoring systems for predictive maintenance

Military and aviation radar systems rely heavily on spinning electrical connections to transmit signals between rotating radar antennas and stationary control systems. These devices must ensure low electrical noise and high data integrity under harsh operating environments.

Advanced rotating connector electrical assemblies for defense use often combine electrical, RF (radio frequency), and fiber-optic channels in a hybrid design. This allows simultaneous power and data transmission with minimal interference.

Advantages for defense applications:

Low insertion loss and excellent signal shielding

Designed for continuous rotation at high speeds

Operates reliably in temperature ranges from -40°C to +85°C

Can be integrated with slip ring-based azimuth systems

In medical technology, rotating electrical connections are essential for devices like CT scanners, MRI tables, and surgical robotics. These machines rely on high-speed rotation to capture precise diagnostic images or perform automated procedures.

For example, in a CT scanner, the X-ray tube rotates rapidly around the patient while data and power must be continuously transmitted to and from stationary computers. The spinning electrical connection ensures this happens without data loss or mechanical failure.

Key benefits:

High-speed data transmission with low signal noise

Compact and lightweight designs for medical use

Long operational life with minimal maintenance

Support for both power and Ethernet-based data channels

In continuous production lines—especially in packaging and printing—rollers and spindles must rotate at high speeds while performing precise electrical and control operations. The rotating electrical connection enables sensors, heaters, and actuators to operate efficiently without interrupting the rotation.

Similarly, textile machines use rotating connectors to power spindles and control yarn tension, contributing to uniform fabric quality and production efficiency.

Benefits for industrial machinery:

Stable current flow at high RPMs

Reduced machine downtime due to fewer cable failures

Simplified system integration and compact footprint

Support for both analog and digital control signals

In marine applications such as ship cranes, subsea winches, and underwater robots, rotating electrical connections ensure continuous signal and power transmission in dynamic environments. These connectors must resist corrosion, high pressure, and saltwater exposure.

Advantages for marine use:

IP65–IP68 waterproof protection

Corrosion-resistant stainless steel and anodized aluminum housings

Reliable under vibration and temperature fluctuations

Suitable for deep-sea data collection systems

Aircraft radar antennas, gimbal systems, and satellite communication arrays depend on rotating connector electrical components for continuous 360° rotation. These precision assemblies must operate flawlessly under vacuum, radiation, and wide temperature variations.

Unique advantages:

Ultra-low electrical resistance and weight-saving aluminum housings

EMI/RFI shielding for noise-free data transmission

Space-grade materials and surface coatings

High reliability with MTBF exceeding 100 million revolutions

Entertainment and stage lighting systems often use spinning electrical connections to allow full rotation of lighting trusses, rotating platforms, or amusement rides. These connectors deliver power, lighting control signals, and sometimes even network data, ensuring smooth operation and safety compliance.

Benefits:

Prevents wire tangling during 360° rotation

Supports multiple circuits for lights, motors, and sensors

Quiet operation ideal for theaters or performance venues

When choosing a rotating electrical connection, several design parameters should be evaluated:

Current & Voltage Ratings: Determine the power requirements of connected devices.

Rotational Speed: Ensure the slip ring can handle the system’s RPM without overheating.

Signal Type: Choose between power-only, signal-only, or hybrid transmission models.

Environmental Protection: Select models with suitable IP ratings for dust or moisture resistance.

Material Quality: Gold contacts offer lower resistance and longer life, while graphite is suitable for high current.

Inspect the rotating joints for dust buildup and wear every 3–6 months.

Avoid excessive load beyond rated current and voltage limits.

Use non-corrosive lubricants or contact cleaners if recommended by the manufacturer.

Ensure proper grounding to prevent noise or interference in signal lines.

Following these steps can extend the operational lifespan of your rotating connector electrical system and reduce downtime.

The rotating electrical connection is a cornerstone of modern mechanical and electrical integration. It enables the seamless transfer of power and data in dynamic systems, ensuring both safety and performance. Whether in wind energy, robotics, aerospace, or medical technology, the spinning electrical connection continues to drive innovation by enhancing system flexibility and reliability.

As industries move toward higher levels of automation and connectivity, the demand for advanced rotating connector electrical solutions will continue to rise — making them indispensable in the era of smart manufacturing.

Phone: +86 13622631318

Email: info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2025 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions