Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2025-10-10 13:58:23

In modern industrial machinery, continuous rotation often coexists with the need to transfer fluids, air, steam, or even electrical signals between stationary and rotating parts. This challenge is solved by an innovative device known as a rotary joint, also called rotating unions. Among the advanced solutions in this field, the RQ Series Rotary Joints stand out for their durability, versatility, and precision engineering. This article will explore how a rotary joint works, its internal mechanisms, application fields, and why products such as the RQ Series have become a standard choice among rotary joints manufacturers worldwide.

A rotary joint is a mechanical device that connects a stationary supply line to a rotating machinery component to transfer media such as water, oil, steam, air, hydraulic fluids, or electrical signals. It enables uninterrupted flow while the rotating part spins at high speed. Rotary joints are essential in industries such as printing, steel processing, plastic molding, textiles, food machinery, and aerospace.

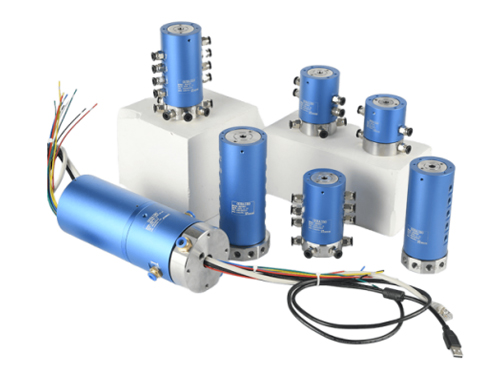

The RQ Series Rotary Joints are engineered to provide robust sealing, high-speed capability, and multi-media compatibility, making them suitable for both heavy-duty and precision applications.

To understand the working principle, let’s break down the major internal components and their functions:

Housing: Fixed part that remains stationary, providing the structure.

Rotor (Shaft): The rotating part connected to the machine.

Seals: Prevent leakage between rotating and stationary sections.

Bearings: Support rotation and ensure smooth movement.

Inlet/Outlet Ports: Channels for transferring the fluid or gas.

Media Entry: The media (water, oil, steam, or air) enters through an inlet in the stationary housing.

Sealing Control: High-precision seals ensure that the fluid does not leak while the rotor spins.

Rotation: The shaft of the rotating joint connects to the rotating equipment, allowing fluid to flow through while maintaining rotation.

Flow Exit: The media exits through the rotating side, maintaining constant pressure and flow.

Automatic Compensation: In high-end series such as RQ Rotary Joints, the sealing surfaces are designed to self-adjust to wear, ensuring long life.

For Electrical Rotary Joint versions, electrical Slip Rings are integrated into the body to transfer electric signals or power alongside fluid.

The RQ Series Rotary Joints are designed for high-performance demands, offering superior sealing performance, long life, and compatibility with multiple fluid types.

High-Speed Operation: Capable of handling high RPM machinery.

Dual or Single Flow Types: Supports one-way or two-way fluid circulation.

Advanced Sealing Technology: Mechanical seals provide zero-leakage operation under pressure.

Multi-Media Capability: Compatible with hot oil, water, steam, air, and hydraulic fluids.

Modular Design: Easy maintenance and part replacement.

Built with precision-machined stainless steel or brass housings.

Dynamic sealing systems for minimal friction and wear.

Optional integration with Electrical Rotary Joint features.

| Model Type | Model Type | Model Type |

| RQ-W Series | Water Cooling Systems | Cold/Hot Water |

| RQ-O Series | Oil & Hydraulic Systems | Thermal Oil |

| RQ-S Series | Steam Transfer | Steam/Compressed Air |

| RQ-E Hybrid | Power + Fluid Transfer | Electric + Fluid |

This product range gives engineers flexibility in selecting precise models to match process requirements.

Used to transfer hot water and oil through rotating cylinders in steel processing.

Provides thermal oil circulation to maintain mold temperature.

Maintains heat in rollers for uniform printing and drying operations.

Used in rotating dryers, cooking drums, and bottling systems.

Rotating unions integrated with electrical rotary joints transfer both hydraulic fluid and electronic control signals in wind turbines and solar trackers.

Leak-Free Operation – Precision-sealed to prevent fluid escape, protecting machinery.

High Durability – Built with corrosion-resistant materials, ideal for harsh conditions.

High Temperature & Pressure Tolerance – Suitable for steam, oil, and pressure systems.

Low Maintenance – Self-lubricating seals reduce wear, extending service life.

Customizable – Available from leading rotary joints manufacturers with custom ports, threads, and mounting specifications.

Ensure perfect alignment between rotary joint and machine shaft.

Avoid excessive hose weight—use support brackets.

Use thread sealant or PTFE tape to prevent leakage.

Inspect seals and bearings every 6-12 months.

Keep inlet filters clean to avoid contamination.

Do not exceed recommended pressure and temperature ratings.

The RQ Series Rotary Joints embody advanced mechanical engineering, enabling continuous flow and electrical communication across rotating platforms. Their intelligent design, high-end sealing, adaptability to heat and pressure, and ability to work with multiple media make them an industry benchmark.

Whether in heavy industrial mills, precision robotics, or thermal systems, rotary joints are indispensable components. By understanding how a rotary joint works, engineers and machine designers can enhance performance, reliability, and safety in rotating systems.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions