Information

Focus on RHD Precision Industry - Get to know the new information of the industry quickly!

2025-08-28 17:17:41

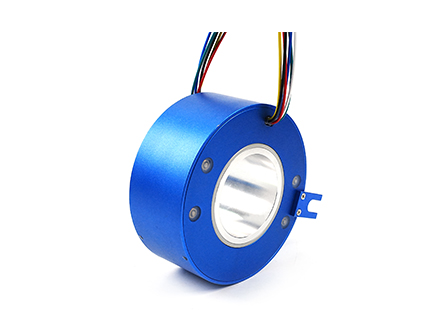

A slip ring is an electromechanical device that allows the transmission of electrical power, signals, or data between a stationary structure and a rotating part. It enables continuous rotation while maintaining an uninterrupted electrical connection, solving the problem of twisting or tangling wires in rotating systems. Slip Rings are commonly used in machinery, robotics, wind turbines, radar systems, medical equipment, and various industrial applications.

Modern Slip Rings are designed for high reliability, compact size, and efficient performance. Typical specifications include:

Voltage rating: 24–600V AC/DC depending on the application.

Current rating: 2A–50A per circuit.

Rotational speed: Up to 6000 RPM for high-speed applications.

Number of circuits: Single to 60+ circuits for power, signal, or hybrid applications.

A slip ring ensures uninterrupted electrical connection between stationary and rotating components. For example, in a rotary radar antenna, a slip ring maintains signal integrity while the antenna rotates 360 degrees continuously. High-quality Slip Rings achieve contact resistance as low as ≤0.01 Ω, ensuring stable signal transmission and minimal power loss.

Modern slip rings can support multiple circuits, allowing simultaneous transmission of power, analog signals, and digital data. A hybrid slip ring can combine 10 circuits of power (10A each) with 12 signal circuits for sensors and communication, reducing system complexity and saving space.

Slip rings are designed to fit in limited spaces while supporting high performance. Typical outer diameters range from 20 mm to 150 mm, and modular designs allow easy customization for specific applications. High-speed slip rings are often lightweight and optimized for low inertia, which is critical in robotics and aerospace systems.

High-quality slip rings operate at rotational speeds up to 6000 RPM or more with low electrical noise (<10 mΩ), making them suitable for sensitive signal transmission, such as in medical imaging devices, precision robotics, or radar systems. Gold-on-gold contact rings are often used to reduce signal interference and increase lifespan.

Industrial slip rings are designed to withstand harsh environments, including high humidity, dust, vibration, and temperature variations. Typical service life ranges from 10 million to 50 million revolutions depending on design and maintenance. Brush materials such as silver graphite or precious metals ensure low wear and consistent contact over time.

Slip rings are widely used in various industries to enable continuous rotation without interruption of electrical connections:

In wind turbines, slip rings transmit electrical power and signals from the rotating nacelle to the stationary tower. Modern slip rings in wind energy applications support currents up to 50A per circuit and high voltage, ensuring stable power generation and control signals for pitch and yaw systems.

Slip rings allow robotic arms to rotate continuously without tangling wires, enabling 360-degree rotation for industrial automation. High-speed slip rings in robotics can reach 2000–4000 RPM while maintaining low contact resistance for precise sensor feedback.

Devices such as CT scanners and MRI machines rely on slip rings to transmit power and data between the rotating imaging system and stationary electronics. These slip rings support high-speed operation (up to 3000 RPM) with extremely low electrical noise, ensuring accurate image acquisition.

Slip rings are essential in rotating radar antennas, turrets, and surveillance systems, allowing continuous 360-degree rotation. High-performance slip rings in defense applications often feature multi-circuit hybrid designs with signal transmission for communications, video, and power.

Slip rings are used in packaging, printing, and textile machines where rotating components need constant power and control signals. Compact and modular slip rings improve machine efficiency, reduce downtime, and simplify wiring complexity.

Proper maintenance is key to prolonging the life of slip rings and ensuring consistent performance:

Clean the contact surfaces to remove dust, debris, or corrosion.

Use lint-free cloths or specialized cleaning solvents suitable for metal contacts.

Some slip rings require light lubrication on brush contacts to reduce wear.

Ensure lubricant does not interfere with electrical conductivity.

Check brushes and rings for wear, pitting, or surface roughness.

Verify contact resistance remains within design limits (typically ≤0.01 Ω).

Ensure the slip ring is properly aligned with the rotating shaft to prevent uneven wear.

Misalignment can increase vibration and reduce service life.

Ensure seals and protective housings are intact to prevent dust, moisture, or corrosive chemicals from affecting performance.

In harsh environments, consider slip rings with IP65 or higher protection ratings.

Professional Data Example: A wind turbine slip ring operating at 30 RPM with 10A per circuit, maintained according to schedule, can last over 20 years without replacement, demonstrating the durability and reliability of well-maintained slip rings.

A slip ring is an essential electromechanical component for any application that requires continuous rotation with uninterrupted electrical transmission. With features such as multi-circuit capability, high-speed operation, compact design, and durability, slip rings are indispensable in wind turbines, robotics, medical devices, radar systems, and industrial machinery. Proper maintenance, including cleaning, inspection, and alignment, ensures long-term performance and minimizes downtime.

For manufacturers, integrating high-quality slip rings into their systems not only enhances operational efficiency but also improves safety, precision, and reliability. As industries continue to demand higher speeds, more circuits, and compact designs, slip rings remain at the forefront of electromechanical innovation, proving their critical role in modern rotating equipment.

Phone: +86 13622631318

Email:info@reehonde.com

Add: Room 301, Building 1, No. 11, Dalingshan Lakeside South 1st Street, Dalingshan Town, Dongguan City, Guangdong Province, China

Copyright © 2026 Dongguan Rui-Hong-De Precision Industry Co., Ltd All rights reserved. Privacy policy | Terms and Conditions